Several companies in North Carolina are now 3D-printing protective face masks to provide locals with relief from the national shortage of N95 respirators.

While the masks aren’t a replacement for N95 respirators, they can be used by first responders as a backup or for people’s personal use. And they have the added benefit of being reusable.

While the masks aren’t a replacement for N95 respirators, they can be used by first responders as a backup or for people’s personal use. And they have the added benefit of being reusable.

Sam Ransdell, the manager of Burney True Value Hardware in Aberdeen, North Carolina has organized a local effort to produce 3D-printed protective masks. He has received over 400 orders in the last few days from all area fire and police stations as well as a number of medical-related businesses.

About four or five local businesses are helping with the production of the masks, including AeroSouth, a small business focused on providing engineering services and products for light aircraft and sailboats.

“Such actions from creative people can not be modeled in predictions of the impact of a virus. Humans are the ultimate resource in tackling any problem,” said Kent Misegades, president of AeroSouth.

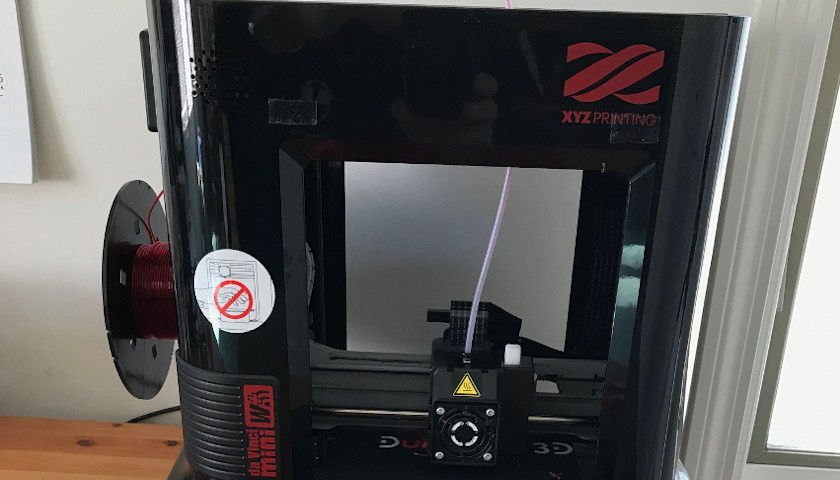

Misegades said he can produce about four masks per day with a 3D printer he generally uses to make prototype parts for small sailboats. He’s using a 3D model designed by La Factoria 3D, a Spain-based company, which was created with the “aim of providing emergency protective material to medical professionals who need it.”

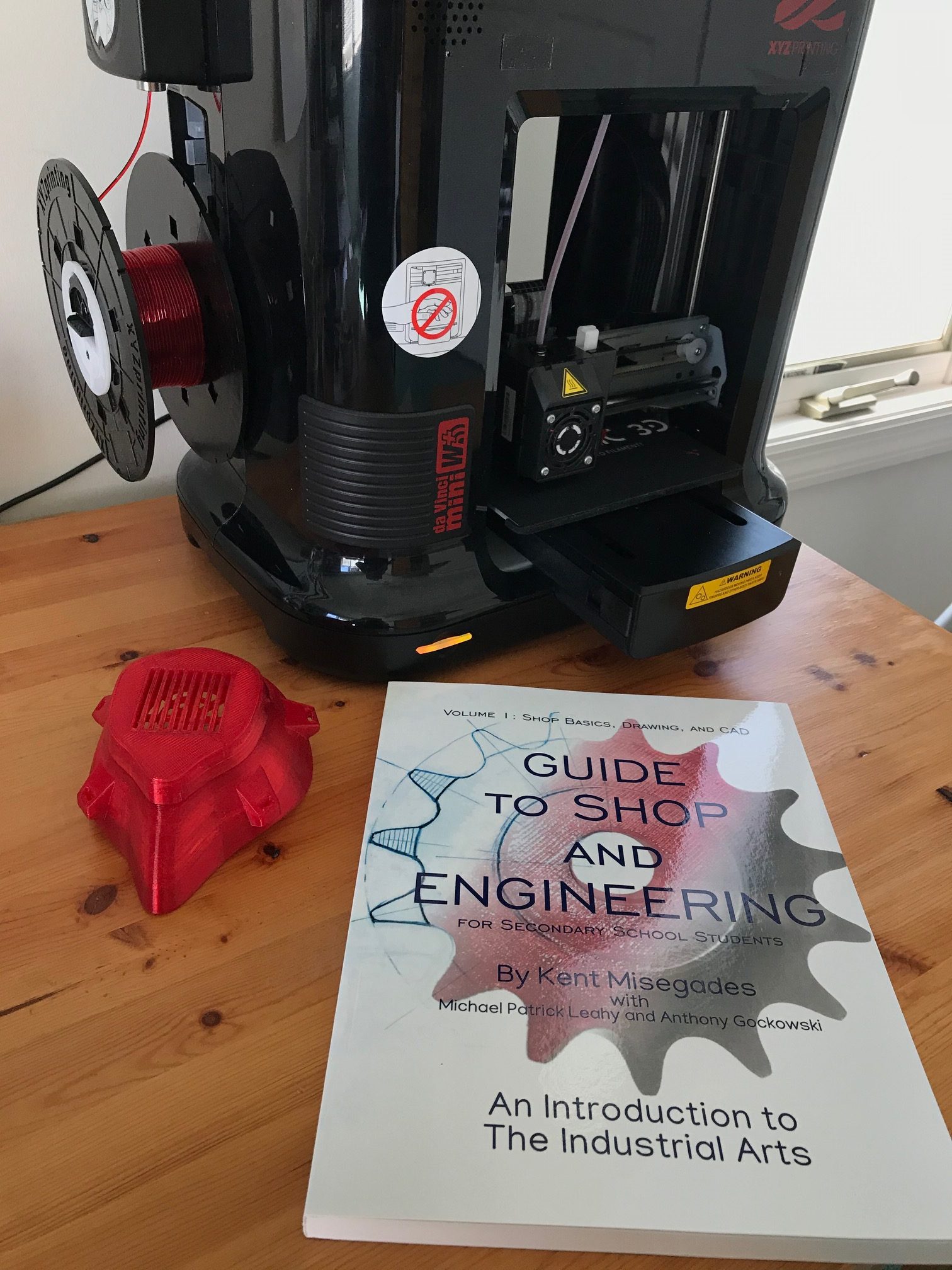

The mask Misegades is printing consists of three parts, including a filter that is “cut out of a 1 micron filter element for a home A/C system,” he said. Each mask takes about five hours total to complete.

The mask is just one of dozens of prototypes being shared on the website Thingiverse, a 3D-printer community where inventors can share their designs. A page on the website called “Hack the Pandemic” is devoted entirely to 3D-printed designs for mask adapters, experimental face masks, and other protective equipment.

Misegades said “anyone can buy a good 3D printer these days for well under $300” and most come with with “everything one needs to get started.”

“So easy, a cave man can do it,” he added, noting that files for 3D-printed designs are free to download, including designs for protective masks.

Misegades is the executive director of the Star News Education Foundation and the author of the “Guide to Shop and Engineering for Secondary Students,” which is being sold at Burney True Value Hardware to pay for the plastic needed for the 3D-printed masks.

– – –

Anthony Gockowski is managing editor of The Minnesota Sun and The Ohio Star. Follow Anthony on Twitter. Email tips to [email protected].